Description

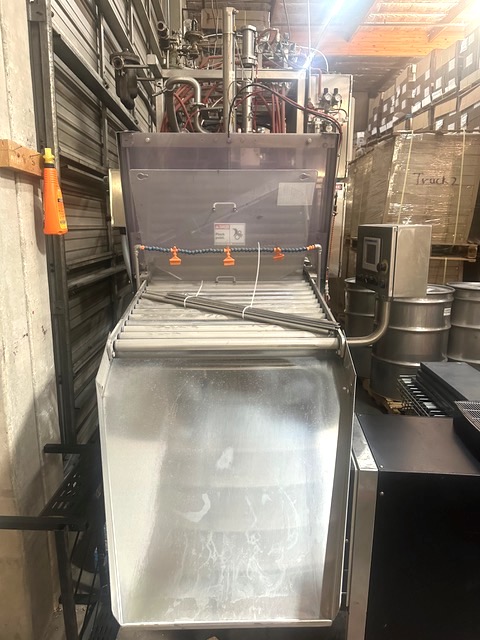

Web Based Filling machine, ideal for aseptic packaging of high-acid food products, including juice concentrates. This robust system is designed for continuous operation and efficiency, significantly reducing energy costs associated with packaging and distribution.

Key features and specifications:

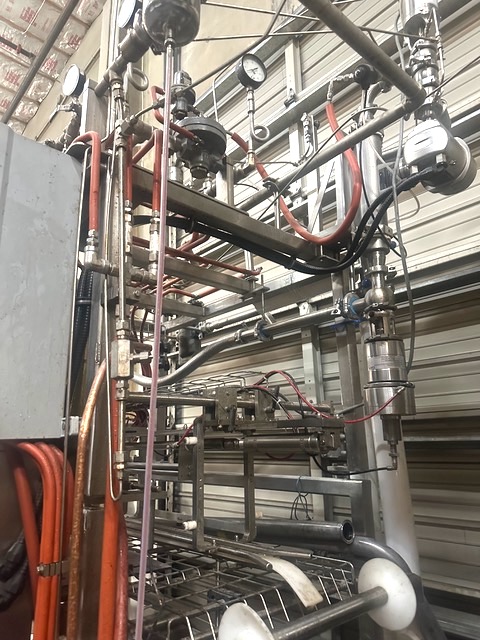

Aseptic Filling Capability: Specifically engineered for aseptic processing and filling, ensuring sterile conditions are achieved and continuously maintained for product integrity.

Automated Sterilization: Features an automatic sterilization cycle that minimizes operator attention, with sterile conditions maintained by a positive sterile air supply and steam. The chamber temperature is precisely controlled between 180°F (82°C) and 205°F (96°C). Fitments are pre-sterilized with saturated steam at 195-205°F (90-96°C).

Automated Filling Process: Automatically feeds pre-sterilized plastic bags from a continuous web, removes caps, inserts the filling head, fills to a predetermined volume, and recaps the bags.

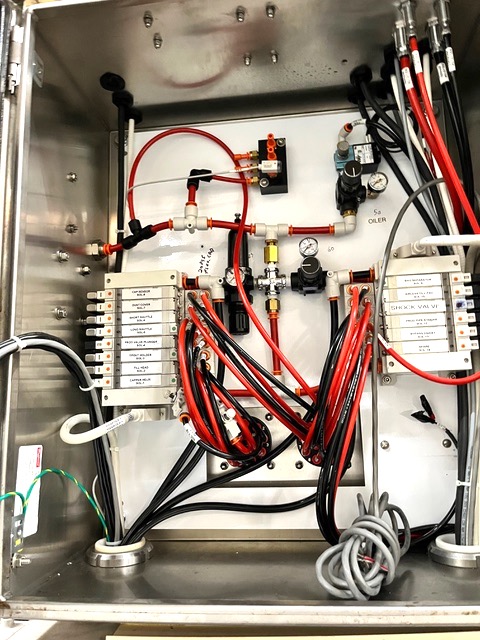

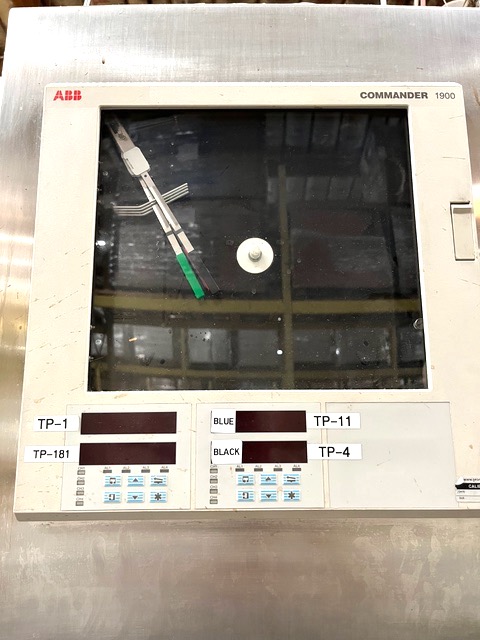

Advanced Control System: Equipped with an Allen Bradley PanelView 600 programmable controller for precise operation , and utilizes a Coriolis mass flow meter for accurate product measurement.

Clean-In-Place (CIP) System: Designed for efficient cleaning with its Clean-In-Place capability.

Flexible Options: Includes options for evacuating excess air (vacuum) and introducing inert gas (nitrogen puff) for optimal product quality.

Utility Requirements:

Compressed Air Supply: 100 PSI @ 15 SCFM (90 PSI minimum).

Steam Supply: Culinary steam regulated to 75 PSI, pre-filtered.

Electrical: Operates on 480 VAC, 50/60 Hertz, Single Phase Minimum, with a step-down transformer to 110 VAC 50/60 Hertz single phase. Also configurable for 208/220/230/240/380/400/460/480/500/575/600 VAC, 50/60 Hertz, 3-phase 1KVA service.

This machine was previously running juice concentrate, demonstrating its proven performance in demanding food processing environments

Download PDF Manual