Description

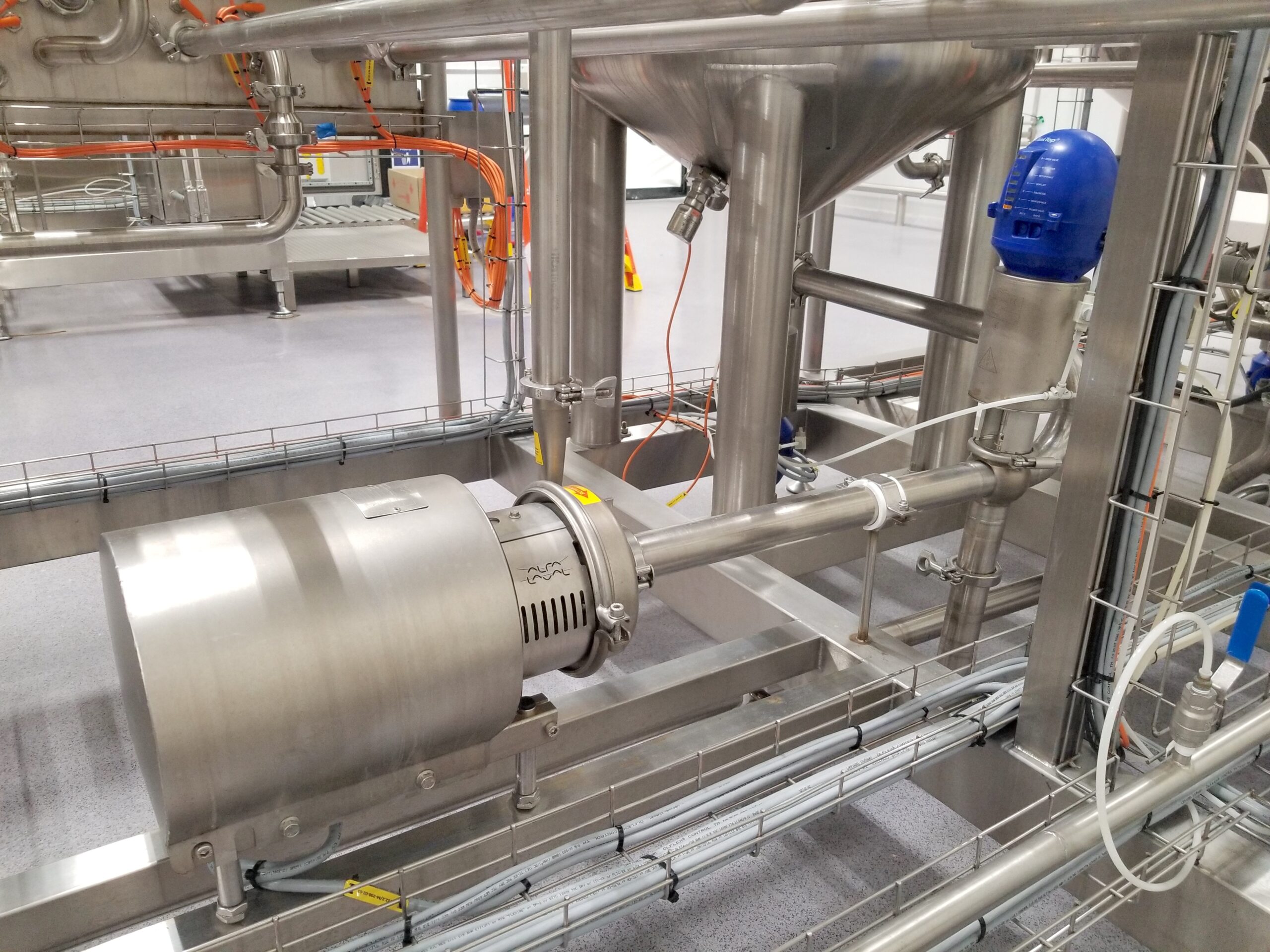

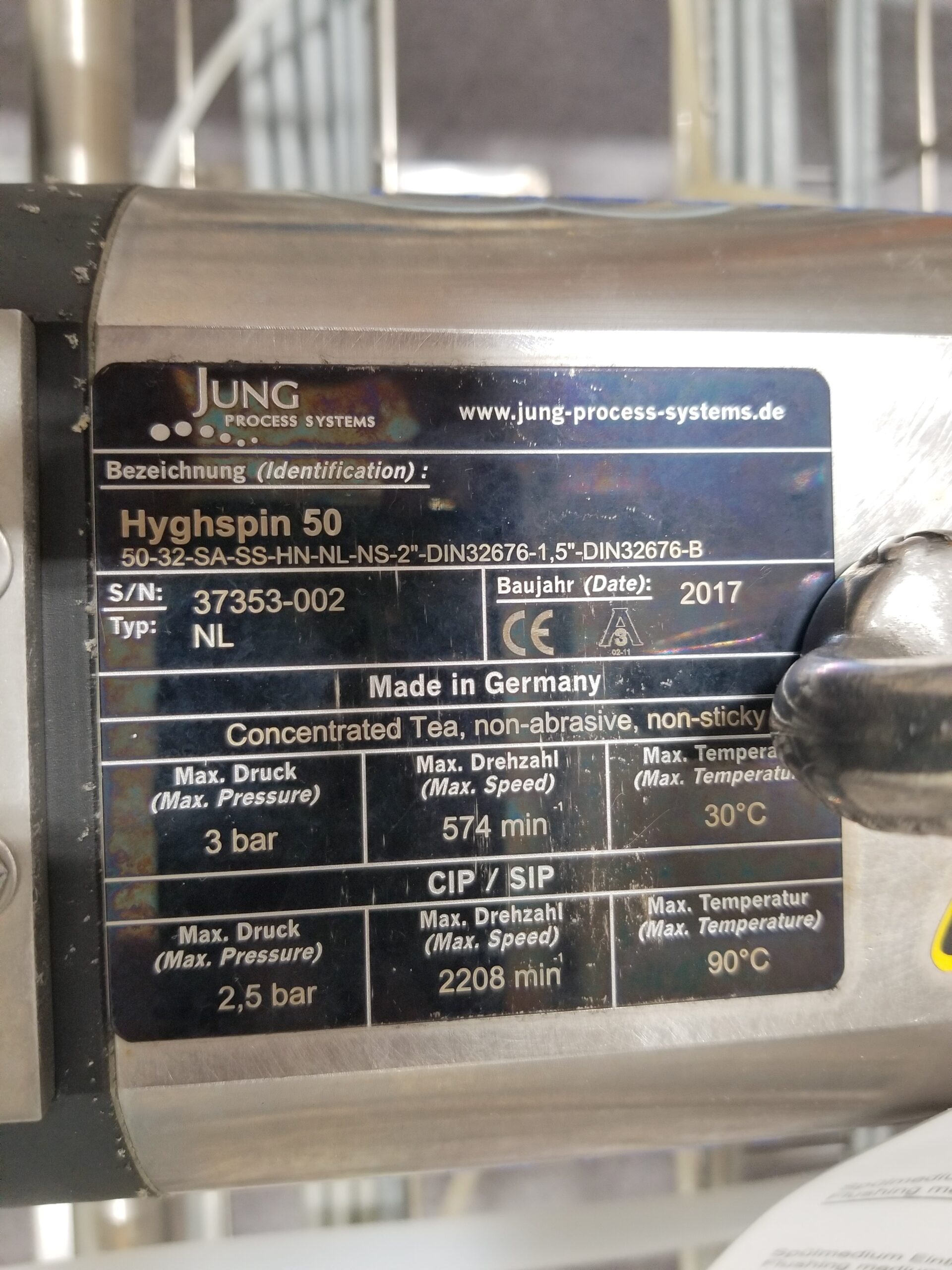

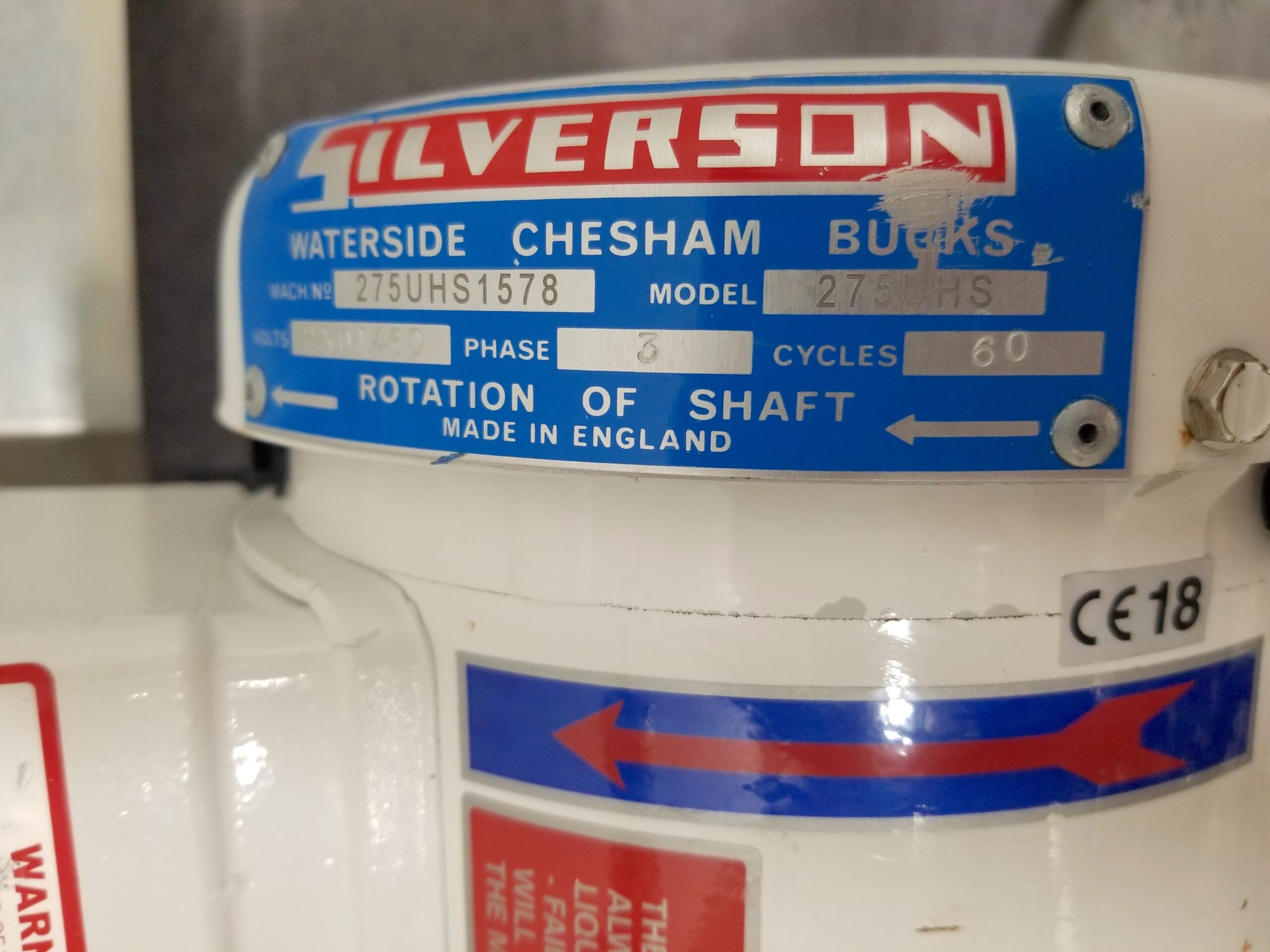

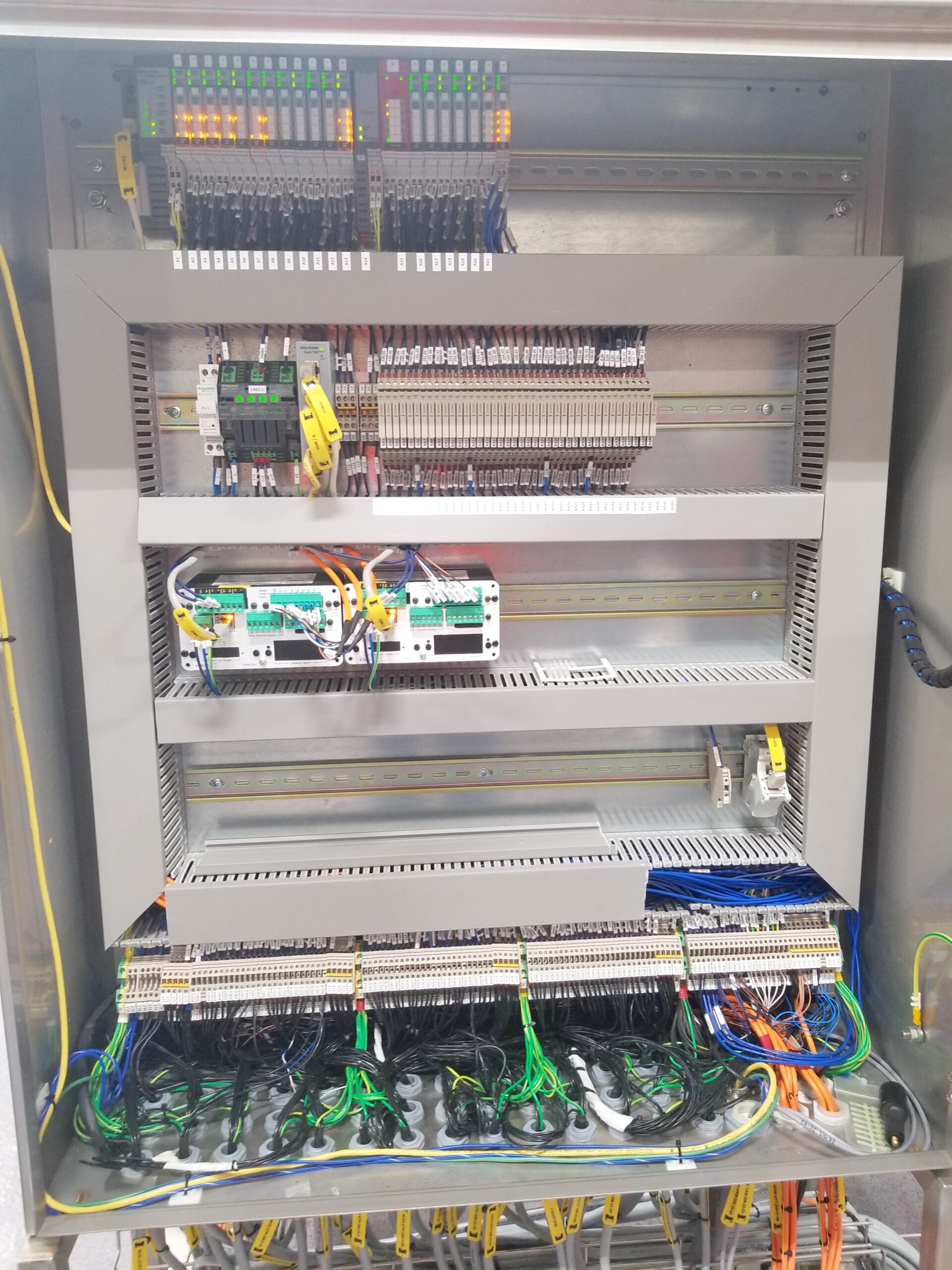

(2) 570 Liter Jacketed Aroma Storage Tanks with Top Mounted Agitation, (2) 1135 Liter Jacketed Blend Tanks with Vak Kisma Top Mounted Scrap Surface Agitation and Mettler Toledo Load Cells, Stainless Steel Frame, (32) Alfa Laval ThinkTop Air Valves – 17 of which are in a valve cluster on back side of skid, (4) Flow Divert Panels, Silverson High Shear Centrifugal Pump, Jung Process Hyghspin 50 Pump, (2) Alfa Laval LKH-5 Centrifugal Pumps, SS Control Panel with Allen Bradley I/O Controls, Last used for Tea Extracts and Flavor/Ingredients Mixing

Description of Operation

All vessels are 300 gallon with jackets suitable for both heating and cooling.

In the process they were at the penultimate stage before Aseptic filling. Concentrated product was brought into the two tanks on the left (looking from the front of the tanks, valve manifolds at rear) and aroma was brought into the two tanks at the right. Aroma was transferred from either of the tanks at the right to either of the tanks at the right to blend to the final product concentration / aroma.

The 2 blending tanks on the left have agitators. The leftmost tank has a homogenising pump (recirculation back into tank and product delivery) the tank second from the just a recirculating/product delivery pump

The pipework is set up to allow for CIP of all pipework and vessels.

All valves are of hygienic design.

The blending tanks are on weigh cells.