Description

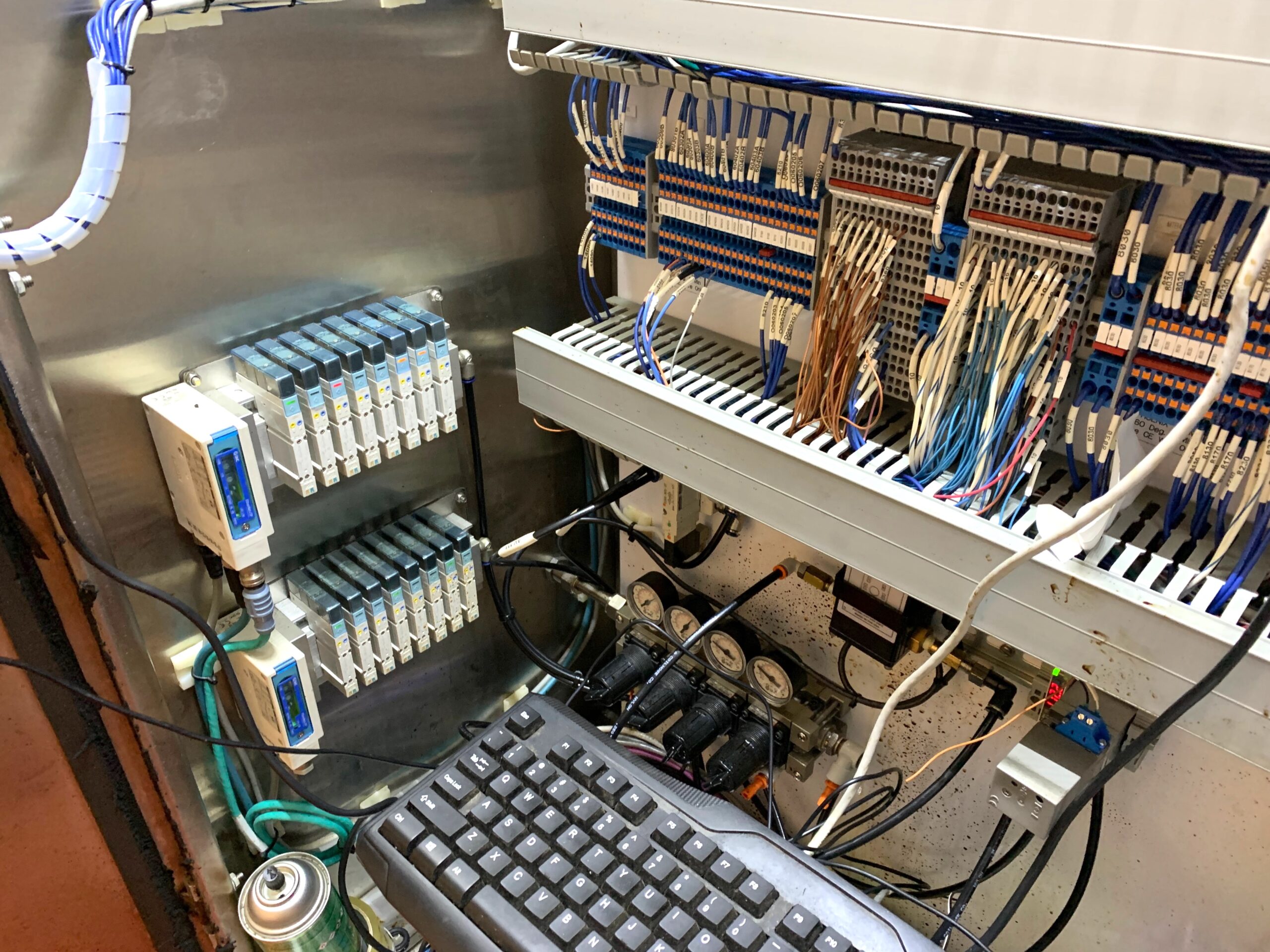

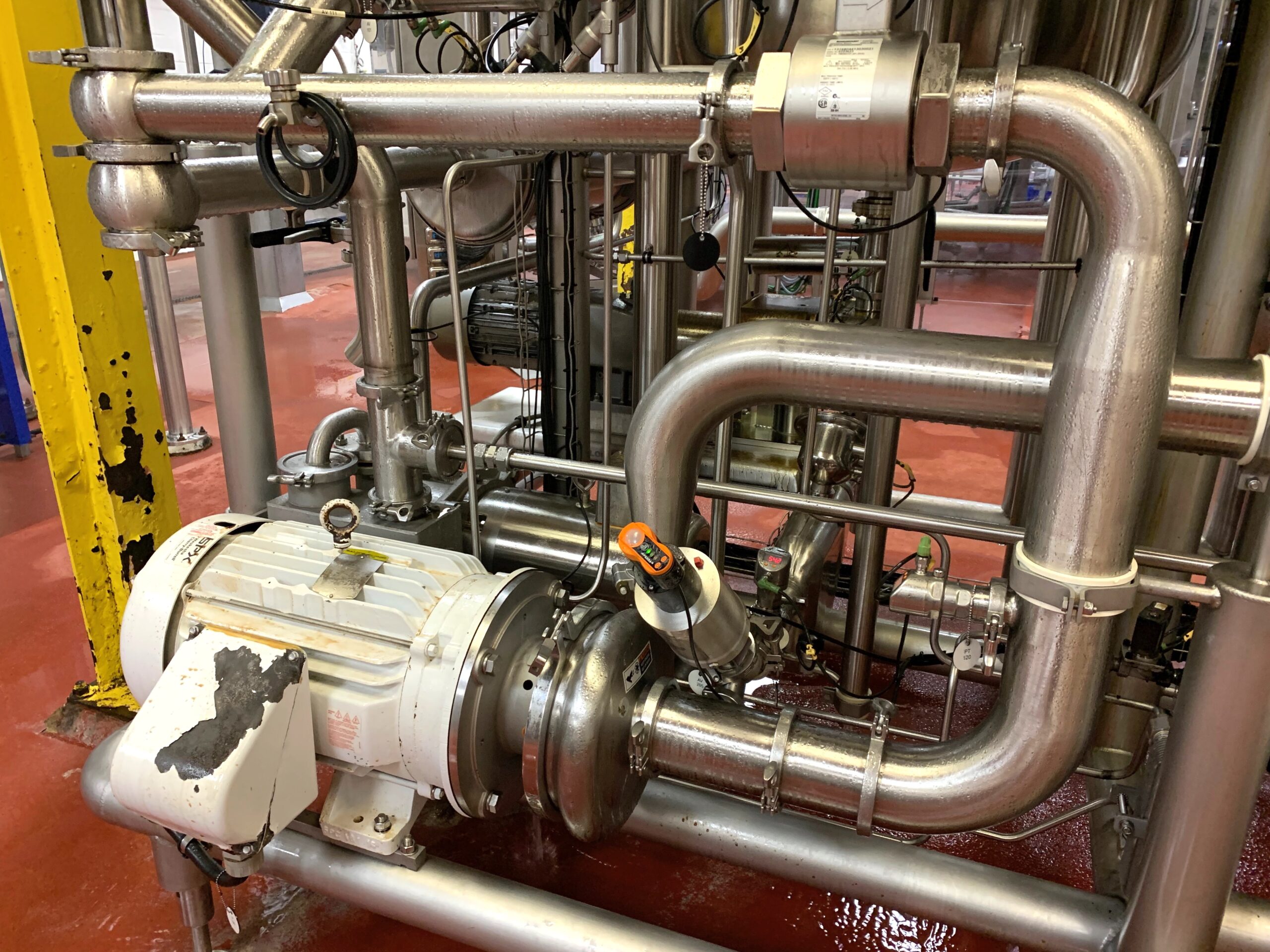

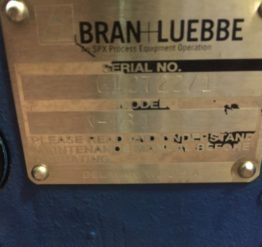

Currently running 650 Bottles/Minute on 20oz. PET Carbonated Soft Drinks, In Production till April 2023, All Stainless Steel Construction, Allen Bradley Logix 5572S Controls with Operator Touchscreen, Allen Bradly 525 VFD Drives, Good Condition, Dell Hard drive Computer Included, This unit blends, dearates and carbonates product in one step, Includes Syrup Interface System to hook up directly to your batch tanks.

This system saves your syrup/water yields over the standard Carbo-Cooler technology. Capable of running soft drinks or juice products.

Our Innopro DCX deaerating and carbonating system will help you prepare both carbonated and non-carbonated table waters for later filling. Using the proven technique of vacuum spray deaeration, which can be performed in either one or two stages, you can either pass on your product straight to the filler or carbonate it inline in an interim step, during which a predefined amount of CO2 will be added to your table water at a rate of 0.5 to 9 g/liter. Our reliable Innopro DCX deaerator/carbonator unit can perfectly process up to 65,000 liters of product an hour.

Besides deaerating and carbonating water for the production of soft drinks this combined unit can also help you dilute and blend various fruit juices. Reliable and precise in its application, our Innopro DCX gives you consistent product quality at the highest level and with minimum maintenance. The low space requirement with an increase in line performance also speaks for our machine.

Deaeration and carbonation in one unit for a perfect symbiosis

Better product quality thanks to optimum water deaeration for perfect carbonation

Product-specific deaeration: one stage for beverages with a low amount of foam and two stages for beverages with a larger amount of foam

Minimize your CO2 consumption with the recipe-controlled buffer tank pressure

Minimize operator intervention with the fully automatic Innopro DCX