Description

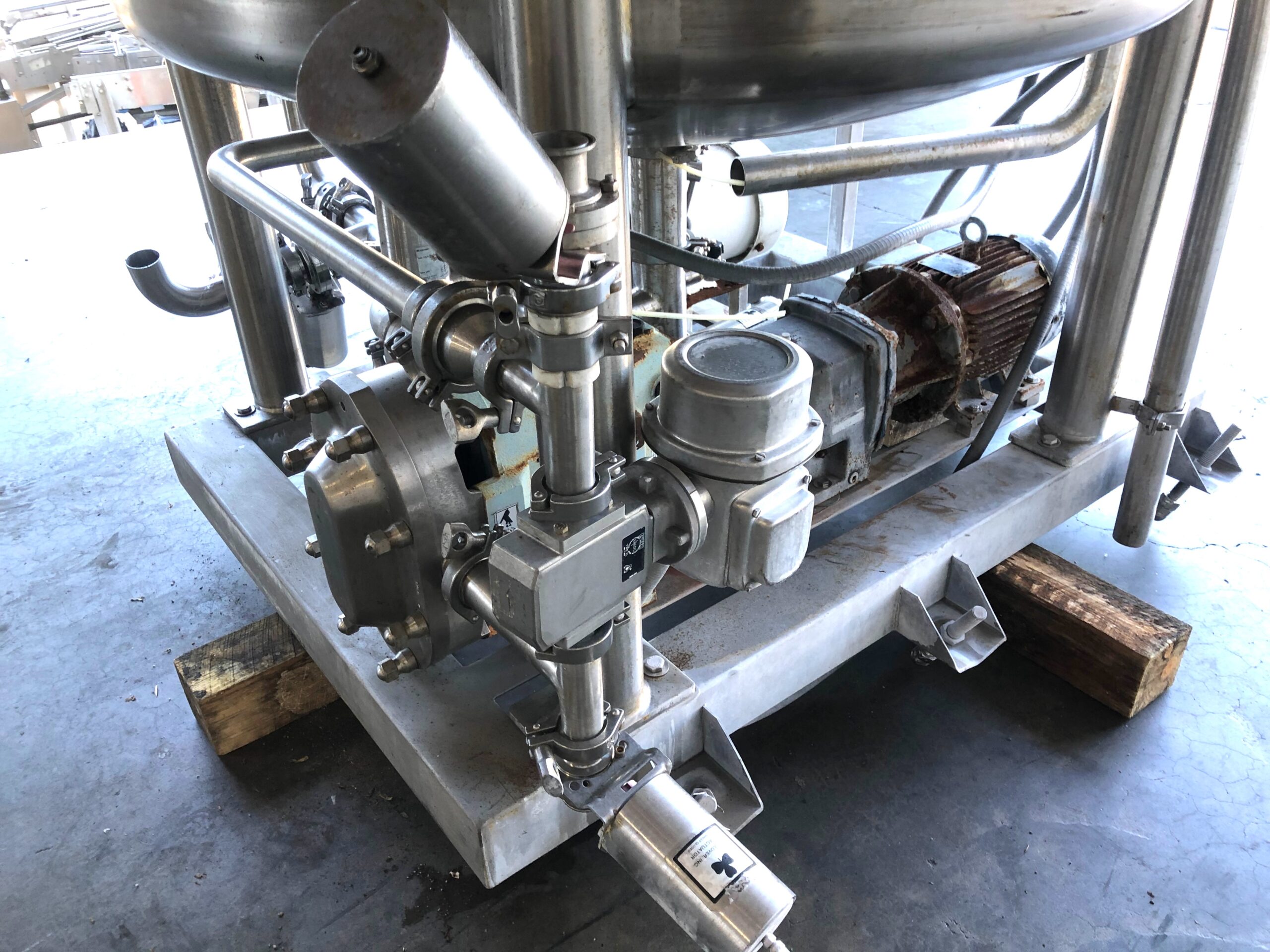

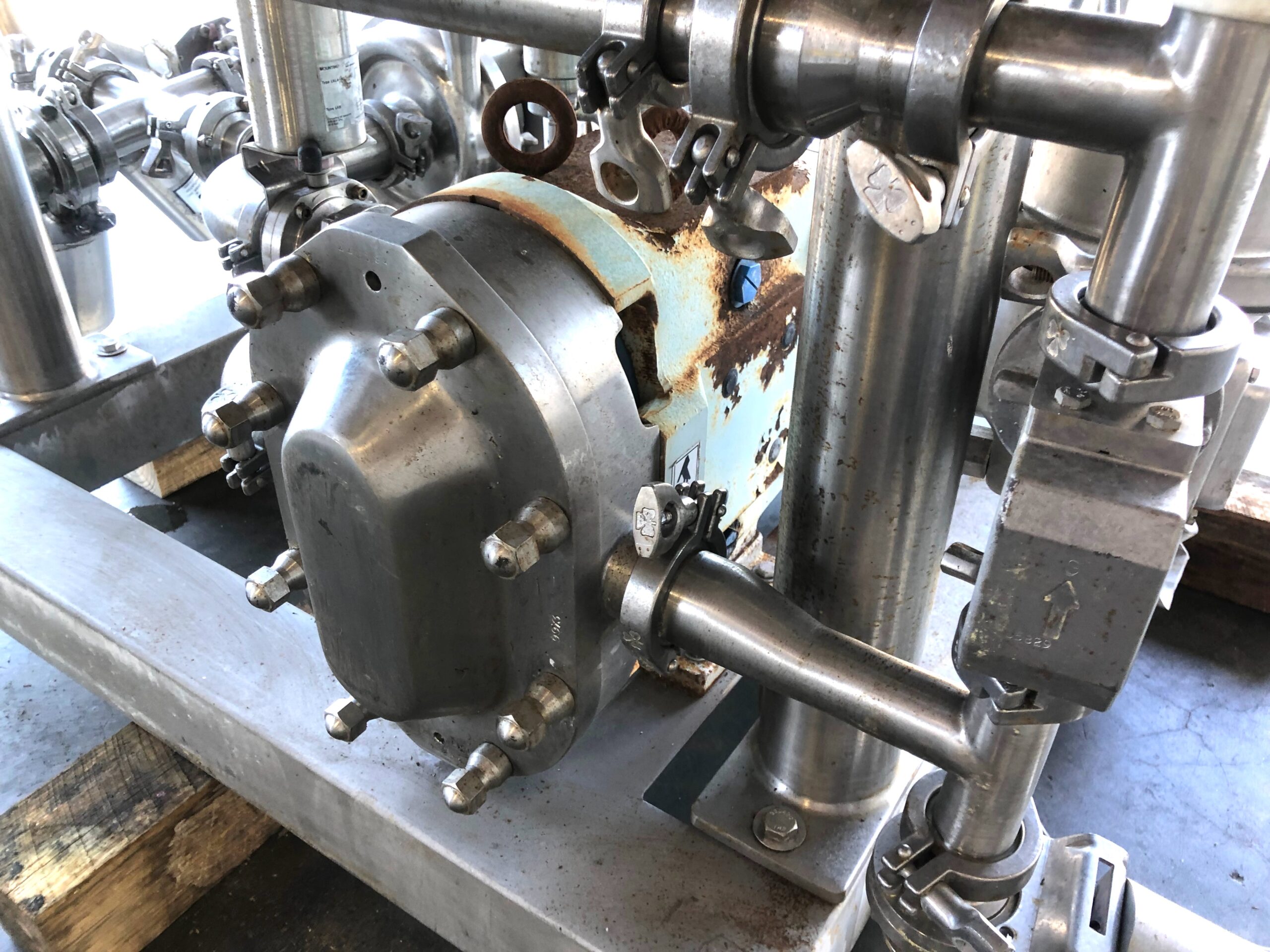

600 Gallon Stainless Steel Tank – Dome Top/Dish Bottom mounted on stainless steel skid with Waukesha 130 Positive Displacement Pump, This system takes finished product with incorrect brix and return it to the blending system – saves on syrup yields and product waste

The Product Recovery System is an automated beverage recovery system that provides production personnel with a function that has never been utilized until now…the functionality of no-dump start-ups, saving gallons of syrup during every flavor change. The system is designed to capture blended beverage that is out of specification due to Assay, CO2 content, or BRIX at any time during production. Once the product is captured, it is slowly metered back into the product flow prior to carbonation, which helps to increase overall syrup yields while reducing BOD surcharges.

The Product Recovery System will retrofit to all types of blenders and will CIP with your existing process equipment.

PRS BENEFITS

Turns disposal problems into profits. Eliminates loss of products caused by residual water at the start of the bottling process.

1. Removes the need to discard product due to improper BRIX or Carbonation Levels.

2. Reduces waste treatment costs.

3. Saves product and man-hours during the production process.

4. Systems only require standard maintenance that can be performed by your

maintenance crew.

5. Our systems enhance the performance of your existing blend system. Why purchase a new blender when the one you have functions fine.